Overview

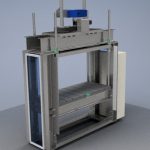

Cambridge Dynamics specialize in the design and manufacture of special purpose machinery and control systems, as well as the improvement of existing production facilities and processes. Cambridge Dynamics has been designing and building special purpose machinery since 1978. During these 38 years we have amassed a large store of knowledge and experience developing a wide range of machines across a diverse array of applications, including a 120 ton forming press which weighed in at 16 tons (see K2 Press in case studies for more information).

- 120 ton Forming Press at a weight of 16 tons on its way to the Customer

Machine Design and Development

Often it is necessary to import because equivalent machines are not available from a UK source. However, Cambridge Dynamics Ltd., have in the past been able to redesign such products, providing greater efficiency, and a wider versatility and then supply the unit at a competitive price. This has led to increased sales through price advantage, increased product versatility, quicker deliveries and ex-stock UK spares. If customers require the equipment to be tailored to their own requirements, this too can be easily and quickly accomplished.

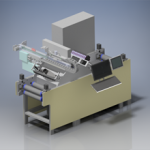

Electrical and Electronic control systems

Electrical and Electronic control systems are designed and assembled ‘in house’ to suit each project and these vary from simple control panels to sophisticated solid state and computer controlled systems.

Cambridge Dynamics is capable of offering advanced functionality such as operator free processes, remote access and automated reporting. In addition, Cambridge Dynamics offers Business Intelligence (BI) integration which allows for the statistical analysis of production data in order to facilitate continuous improvement.

Design Capabilities

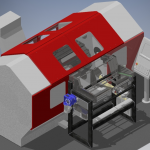

- CAD Design using Autodesk CAD/CAM Products including up to and including 5 axis simultaneous CAM. All of our CAD/CAM work is done by qualified engineers and design draughtsmen.

- Concept to commissioning of all manner automated equipment. Our systems have utilized pneumatic, hydraulic and electric actuation for tasks including handling, assembly, bending, turning, welding and cutting. Ask for a list of completed projects. If it can be done, we can automate it.

- Start to finish tool, die, and jig design and manufacture.

- Fabrication of work and measurement stations, check fixtures, frames, stands, and tables to complement our automation equipment.

- Machines

Precision Tool & Die Manufacture

Cambridge Dynamics is capable of manufacturing high accuracy punch and die sets using the latest in CNC electro-discharge machining (EDM). Furthermore, using CNC milling, and both surface and cylindrical grinding, most types of precision tooling can be manufactured. This can be done in large quantities or as one off pieces.

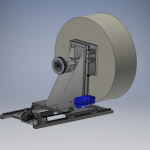

Hydraulic Control Systems

We have considerable experience in the use of Moog hydraulic and brush-less electric servo systems, and have a number of successful implementations based on the Moog digital servo controllers.

Hydraulic Control Systems which are compact, versatile and powerful, are being increasingly used throughout industry and again in this area Cambridge Dynamics can offer a personalized service.

System designs can be tailored to suit individual requirements with static or portable power packs driven by electric motor, diesel or petrol engine and often one manifold can be designed to accept and interconnect all the valves in a system providing an easy to maintain unit.

Many companies are beginning to appreciate the advantages of hydraulic control with requests to replace slower, outdated mechanisms with faster, more powerful hydraulic systems and with a substantial background in special purpose machines, Cambridge Dynamics can supply the whole package.

Other Capabilities

Other areas of business include feasibility studies for machine or process proposals and for intended patent applications. In this area a confidential service is provided and clients can be advised on the viability of engineering proposals before proceeding with more expensive action.

Capabilities- External

We have direct technical agreements with providers of the following capabilities:

- Large machining works for precision machining of components up to 5m x 3m and weighing up to 5 tonnes.

- Industrial design and prototyping specialists with product design and prototyping expertise and 3d printing, vacuum molding, injection molding and custom circuit design capabilities.