One of the services available from Cambridge Dynamics is the bespoke manufacture of machine parts and precision tooling items using specialist CNC milling tools and turning techniques.

CNC stands for Computer Numerical Control. As a team of seasoned CAD/CAM software experts from various manufacturing disciplines, we have the capacity to produce a wide range of components, from one-offs to high volume orders – and, if required, our team can undertake the manufacture and finishing of complete assemblies.

So, what exactly is CNC milling and turning, and how might it be of use to you? Read on to find out more about these highly accurate techniques.

Types of CNC Milling Machines

CNC milling machines work using a cylindrical cutter that shapes materials by drilling into them from different angles and at different speeds and pressures in response to a detailed specification. The most commonly milled materials are woods and metals.

Most CNC milling machine tools can come in a variety of shapes and sizes. Depending on the machine model, this component can use between 2 and 5 axes to create different slots. This enables the device to create anything from simple holes to complex shapes that involve multiple rotations.

At Cambridge Dynamics, we employ CNC milling techniques for many projects, and all of our milling machines are automated by way of computer programming. Our experts enter the required dimensions and any other relevant data to achieve the tightest possible tolerance.

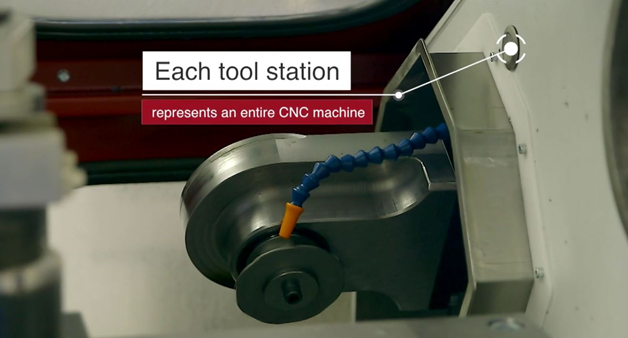

CNC Turning

“Turning” usually involves the use of a lathe or turning centre to “sculpt” or “carve” a piece of material into the correct form.

In this computer-aided manufacturing process, the item to be shaped is attached to a “feeder” and placed inside the machine, where it is moved or rotated as the lathe removes the correct areas of material.

A CNC turning machine can be programmed with extreme dimensional accuracy to ensure that the correct amount is removed automatically at high speeds.

Some types of CNC turning equipment also have milling capabilities, streamlining the process significantly.

Our CNC Machines and Services

Cambridge Dynamics should be your first port of call for exceptionally accurate CNC milling projects and turning operations. When it comes to the production of fully featured 3D assemblies of superior quality, our team of experts leads the way.

Alongside our turning and milling services, our fully equipped premises enable us to offer a full complement of solutions, from initial machine concept and design to manufacture, assembly, testing, finishing, and delivery.

We can work to commission, assisting you throughout a project or simply providing one-off components.

To discuss anything from the expertly automated milling and turning of precision parts to the fabrication of whole machines, simply get in touch today using our online contact form.

We’ll be happy to provide any advice you require or start working with you on your first order.

The Cambridge Dynamics team is capable of producing high–performance parts based precisely on your specifications, so we encourage you to provide as much information and detail as possible when making an enquiry.

We look forward to hearing from you.

FAQs

What is CNC milling and turning?

CNC milling and turning are both types of CNC technology, which manufacturers often use to create more intricate parts. The initials CNC refer to Computer Numerical Control, whereby computer-aided design software translates a 3D model into code, which then guides the tools in the machine.

The lathes, mills, grinders, and routers will move whenever and however the computer instructs them to, cutting away excess material to produce the desired shape based on the 3D model. Many sectors use this versatile technology for its increased precision and output, such as the electronics and automotive industries.

Though all CNC machining follows the same workflow explained above, the specific hardware and capabilities can vary. This is why CNC milling and CNC turning are actually two different processes. Milling involves using a rotating multi-point tool to cut the stationary material, while turning involves rotating the material to cut it with a stationary single-point tool.

CNC milling works with various materials such as metals, alloys, and thermoplastics, while unsuitable materials include hard ceramics, soft rubber, and silicone. CNC turning is best for creating conical or cylindrical parts, while CNC milling is good for everything else. Sometimes, both techniques are used on the same piece, depending on the design and specific features required.

What are the benefits of CNC milling operations?

CNC milling is renowned for its high precision, consistently exceptional results, repeatability, and outstanding speed. These features mean your business can enjoy the ability to mass-produce parts reliably, ensuring efficiency and maximum profit.

What’s more, you can benefit from less risk of human error and therefore reduce wasted resources, saving materials, time, and money.

What are CNC milling processes used for?

CNC milling machining processes produce custom components by cutting away pieces of the stationary raw material with computer-controlled tools. The milling system allows the multi-tools to move on 2 to 5 axes – the most common type is the 3-axis, which moves in 3 directions known as X, Y, and Z.

These cutting tools move forward, back, or side-to-side as directed by the computer programme, removing pieces of the material with each pass. This can take longer than turning, as the tools have to do more work to shape the material clamped in place on the machine bed.

These production capabilities are often helpful for the chemical, mechanical, thermal, and electrical industries in particular. Some examples of parts commonly created via CNC milling include:

- Punches for fabricating sheet metal

- Moulds for manufacturing other parts

- Engine blocks and other engine components

- Water pumps for hydraulic equipment

- Spiral or straight gears for various mechanical devices

- Brackets and fittings with custom threads and holes

- Custom enclosures and housing for internal electrical parts

- Surgical instruments, implants, and other medical devices

While 3 axes of movement are generally enough to complete the part, pieces with more complicated geometry may require more axes for greater flexibility. Of course, using 4 or 5 axes will be more expensive than their typical 3-axis counterpart. It’s important to discuss the design with your engineers to find out whether it can be done with 3 axes, or if you’ll need a larger budget.

That said, CNC milling is fast and inexpensive in low volumes, making it ideal for prototypes and limited production runs. The efficient end-to-end process offers swift enough lead times to make it a reliable option. Milling also conserves more material than turning, which helps to keep costs down, and can form more complex parts. It can also be used for post-machining, adding more details after turning, moulding, or 3D-printing parts.

What are CNC turning machines used for?

While CNC machining operations are a relatively modern concept, CNC turning draws upon one of the oldest shaping tools – the lathe. While traditional lathes were operated by manually turning wheels, Computer Numerical Control streamlines the process without needing constant supervision.

CNC turning lathes can precisely perform a variety of operations such as boring, drilling, grooving, and knurling. These computer-controlled machines hold the stock in place with a gripping mechanism known as a ‘chuck’, which then rotates at the required speed. Meanwhile, the tools in the machine’s turret move back and forth to shave away excess material every time they come into contact with the stock.

Since CNC turning achieves the design by removing material, it’s also referred to as subtraction machining. Here are some examples of components often created with CNC turning:

- Industrial rollers with tight tolerances

- Rounded connectors, such as ball joints

- Tolerance-critical parts like nuts and bolts

- Flanges for strengthening pipes and beams

- Tubular barrels for constructing firearms

- Items with cylindrical or conical profiles, like shafts or nozzles

- Rounded turbine blades for the energy production industry

CNC turning is most commonly used to create hollow cylinders, as it’s the most efficient and precise method of CNC precision machining to achieve the desired roundness. It’s possible to do this using a 5-axis CNC milling machine, but it would take much longer, making it a less practical choice.

Since CNC turning can produce small, rounded, or hexagonal parts with tight tolerances much faster, it’s usually the preferred choice for larger production runs with shorter lead times. In some cases, turned parts can then undergo a CNC milling cutting process to achieve further asymmetrical features.