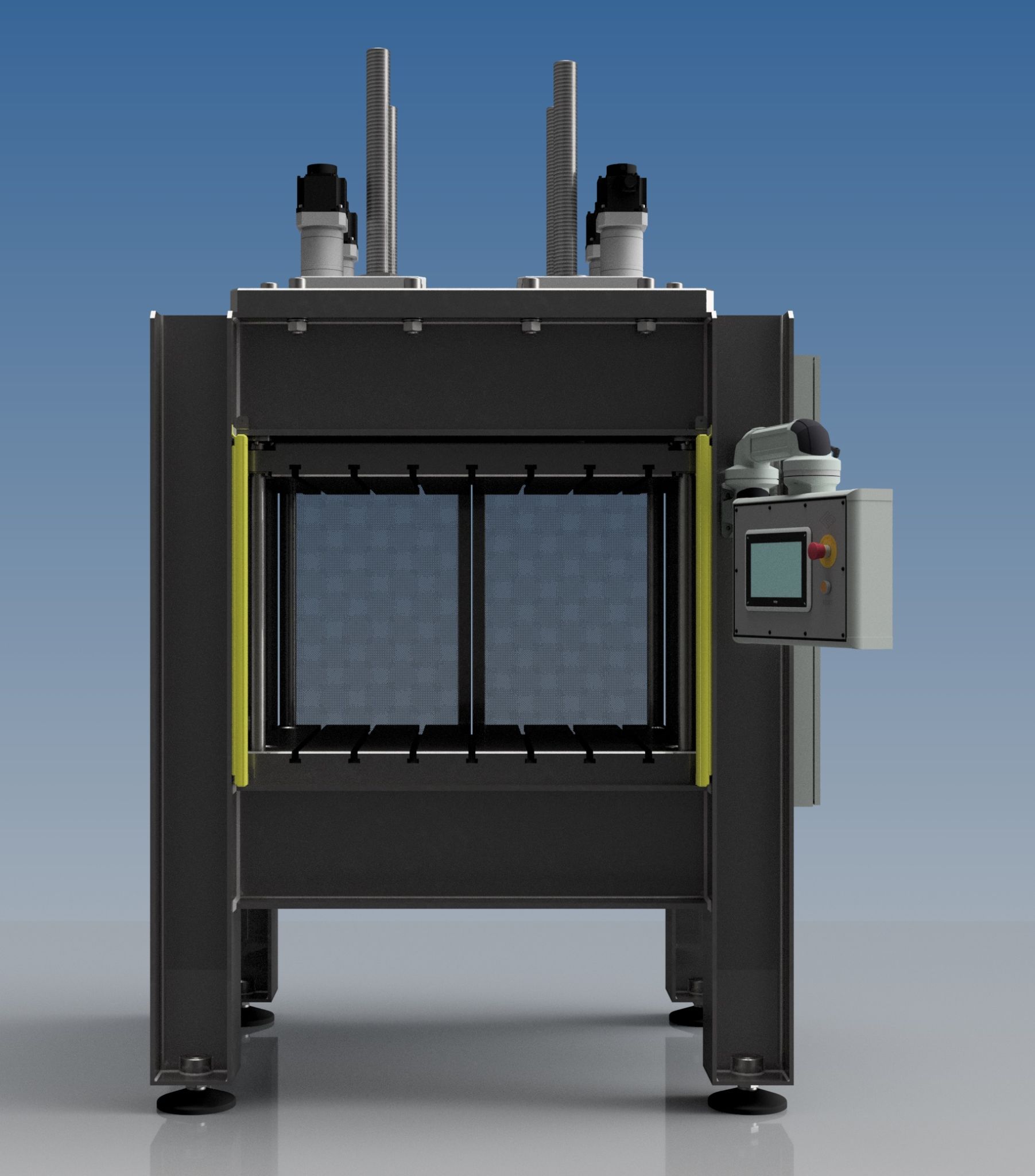

Punch Presses & Stamp Presses

Coils or blanks of metal can be shaped into almost any desired form using an industrial stamping press or punch press machine.

The team at Cambridge Dynamics – experts in the design and manufacture of custom automation equipment – regularly employs this technique in the process of fabricating highly accurate bespoke components and parts to a client’s detailed specification.

Here, we’ll explain a little more about punch & stamp presses, along with a few of our other services, to help you decide whether this process is well-suited to your needs.

How Do Stamp or Punch Presses Work?

The experienced team at Cambridge Dynamics use a punch or stamp press to “press” flat sheet metal into a particular shape.

We automate the process using advanced CNC (Computer Numerical Control) machinery, which enables us to replicate the same results with exceptional precision, time and time again.

For this reason, we are able to produce large volumes of stamped or punched components in very little time.

The tooling used to create the desired results is expertly designed and produced, and can create a wide range of effects, including embossing, bending, blanking, coining, flanging and punching – accurate to the exact criteria provided.

However unique or complex your desired component may be, we’ll be able to produce it in the most precise manner possible. Bespoke fabrication is one of our specialisms, so don’t hesitate to get in touch, even if you’re not completely sure of the part you’ll need.

We can work with you to determine the most practical and effective options for your project.

Why Use Cambridge Dynamics for Your Stamp & Punch Pressing Requirements?

At Cambridge Dynamics, our specialist team – composed of experts in the fields of mechanical, electrical, mechatronic and pneumatic systems – understand the importance of employing the most sophisticated and advanced techniques.

Founded in 1978, we’ve developed highly effective approaches and techniques that always employ cutting edge technology – helping us to remain at the forefront of the industry.

Thanks to the wide range of processes we employ and the diverse array of precision devices at our disposal, Cambridge Dynamics can provide our expertise at any point within the machinery fabrication process.

We’re able to offer services right from initial machine concept and design, to the manufacture, assembly, testing, finishing and delivery of individual parts or whole assemblies.

We can even design and build specialist control systems for your machines.

How to Request Punch & Stamp Pressing Services

Whatever the size or type of project you are pursuing, all you need to do in order to request our services or assistance is to get in touch via our online contact form.

We’ll be happy to hear from you, whether you require answers to certain questions, specialist advice or a means of engaging with our services.

To help us understand exactly what you’re likely to need, we ask that all prospective clients provide as much information as possible when describing their project and the parts required. We can then fabricate all components to the greatest possible degree of accuracy.

FAQ’s

What are punch presses?

A punch press is a machine that changes the size and shape of a piece of metal, which involves placing sheet metal between dies and applying pressure. The punch or ram is an arm which pushes down on the metal and shapes it around a die secured to the bed below. Also known as stamp presses, they can either bend the metal into a specific form or cut out a shape in the metal.

There are several types of punch presses which are powered differently. The ram can be driven by electric motors and a flywheel or hydraulic cylinders, or even programmed by a computer. CNC or computer numerically controlled punch presses offer faster speed and flexibility due to their multi-tool tower turrets.

Stamp presses are an efficient way of mass-producing accurately shaped metal parts in shorter time spans. Higher levels of automation make punch pressing a cost-effective process, with fewer mistakes and less waste. Custom die sets can be made to use with punch presses to create highly specific shapes, designs, and finishes.

What does a punch press do?

An industrial stamping press works by driving a ram with enough force to bend or shear sheet metal around a die form. The result is a specifically shaped metal part that will go on to be used in a final product. This is done much more quickly and using less labour and materials than traditional machining, and far more accurately than could be achieved by hand.

Punch press machines have a balanced rigid frame with welded metal plates for long-term stability and safety. The material for stamping can be placed and moved either manually or via computer programming depending on the type of stamp press. Many kinds of metal are used in punch pressing, including steel, aluminium, copper, and various alloys.

Stamp presses offer a variety of techniques to create customised pieces, including but not limited to:

- Blanking

- Bending

- Coining

- Flanging

- Embossing

- Drawing

- Trimming

- Contouring

- Countersinking

- Centre-punching

- Riveting

- Hemming

Punch presses can produce accurately shaped parts for a range of uses, from nuts and bolts to electric terminals. These stamp-pressed parts are crucial elements in products such as home appliances and construction tools, and are used in many different industries around the world.

Are stamp presses and punch presses the same?

The terms ‘stamp press’ and ‘punch press’ tend to be used interchangeably when talking about the same type of metal pressing machine. Some in the industry may take issue with the lack of distinction, but they are generally the same machine – it’s only the specific processes of stamping and punching that are different.

Both involve manufacturing a part by applying pressure, but stamping only manipulates the shape of the metal, while punching cuts out pieces from the sheet of metal. The stamping process can actually include punching at the end, or the metal can simply be pressed to deform it without breaking it away from the rest of the sheet.

As mentioned above, there are different kinds of stamp presses and punch presses, including mechanical, hydraulic, and CNC machines. The latter is often used for precise cutting or punching, while mechanic or hydraulic presses with dies are used for stamping metal into shapes. While stamp presses and punch presses are the same on the surface, they can be categorised according to the power source and mechanism, the frame type, or the number of rams, slides, or dies.