Ball Screw Presses

Cambridge Dynamics offers a range of servo driven ball screw press units for forming and punching operations. Control is via Fanuc or Mitsubishi controls as per the customer’s preference. All machines are CE marked and are provided with documentation in English.

Ball Screw Press Standard Sizes

020 Frame

| Press Force | No. of Screws | Rapid Speed4 | Stroke1 | Max Platen Size2 | Accuracy3 |

| 5T | 1 | 6000mm/min | Up to 1.5m | 0.8m x 0.8m | 0.05mm |

| 10T | 2 | 6000mm/min | Up to 1.5m | 0.8m x 1.6m | 0.05mm |

| 20T | 4 | 6000mm/min | Up to 2m | 1.6m x 1.6m | 0.05mm |

030 Frame

| Press Force | No. of Screws | Rapid Speed4 | Stroke1 | Max Platen Size2 | Accuracy3 |

| 15T | 1 | 3000mm/min | Up to 1.5m | 0.8m x 0.8m | 0.05mm |

| 30T | 2 | 3000mm/min | Up to 1.5m | 0.8m x 1.6m | 0.05mm |

| 60T | 4 | 3000mm/min | Up to 2m | 1.6m x 1.6m | 0.05mm |

040 Frame

| Press Force | No. of Screws | Rapid Speed4 | Stroke1 | Max Platen Size2 | Accuracy3 |

| 20T | 1 | 1500mm/min | Up to 1.5m | 0.8m x 0.8m | 0.1mm |

| 40T | 2 | 1500mm/min | Up to 1.5m | 0.8m x 1.6m | 0.1mm |

| 80T | 4 | 1500mm/min | Up to 2m | 1.6m x 1.6m | 0.1mm |

050 Frame

| Press Force | No. of Screws | Rapid Speed4 | Stroke1 | Max Platen Size2 | Accuracy3 |

| 30T | 1 | 1500mm/min | Up to 1.5m | 1m x 1m | 0.1mm |

| 60T | 2 | 1500mm/min | Up to 1.5m | 1m x 2m | 0.1mm |

| 120T | 4 | 1500mm/min | Up to 2m | 2m x 2m | 0.1mm |

060 Frame

| Press Force | No. of Screws | Rapid Speed4 | Stroke1 | Max Platen Size2 | Accuracy3 |

| 40T | 1 | 600mm/min | Up to 2m | 1.5m x 1.5m | 0.1mm |

| 80T | 2 | 600mm/min | Up to 3m | 1.5m x 3m | 0.1mm |

| 160T | 4 | 600mm/min | Up to 3m | 3m x 3m | 0.1mm |

1 See Fig below for aperture dimensions

2 Standard platens, other sizes available on request

3 Repeatability ±0.02mm. Ultra-high precision units are available on request

4 Limited for safe operation. High jog speeds available on request, requires additional safety measures

Control System Options

Control of the press is via a touch screen HMI that can be customised to the client’s application. The control is offered in 4 different types:

- Standard – servo motor with load sensing via servo torque monitoring accurate to ±5% of rated capacity. Position measurement via the servo encoder

- Precision Load – servo motor driven with load cell feedback providing precise control of the load < ±0.5% of rated capacity. Individual load cells for precise balancing of forces in multi screw presses.

- Precision Position – servo motor driven with glass linear encoders to provide accuracy of ±5µm. True platen position readout with dynamic position correction.

- Precision Load and Position – Incorporates both 2 & 3 above

All controls come standard with a recipe system allowing the operator to call up pre-defined programs from a list. This can be integrated with RFID or barcode tagging of the press tools.

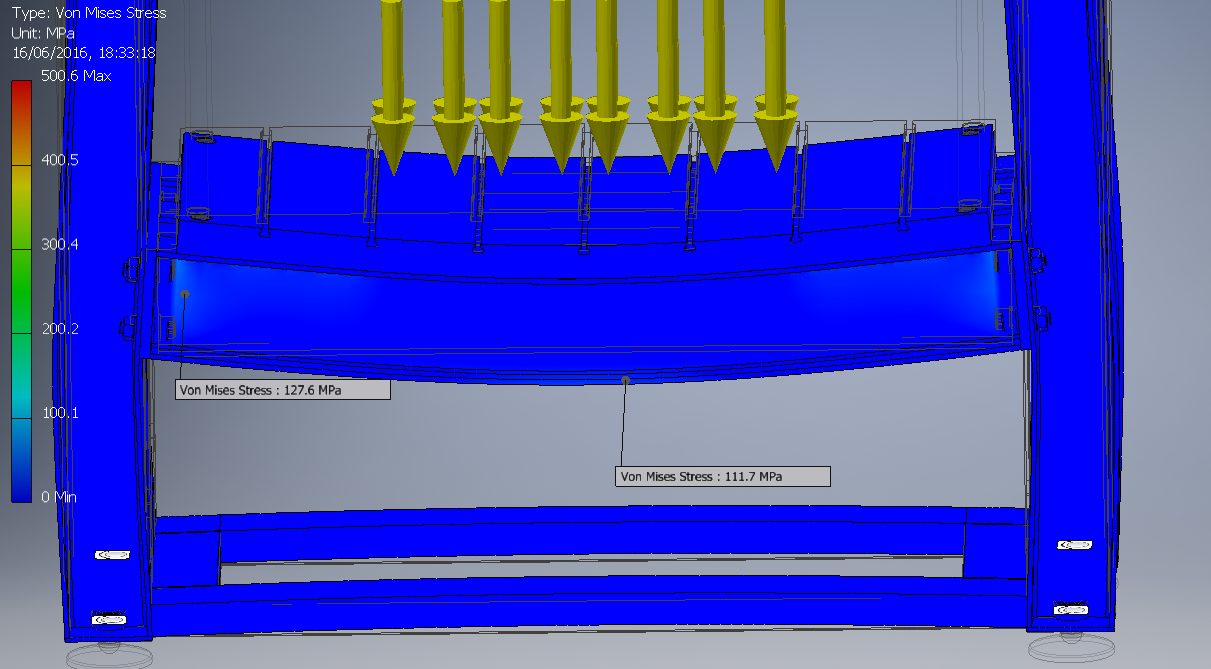

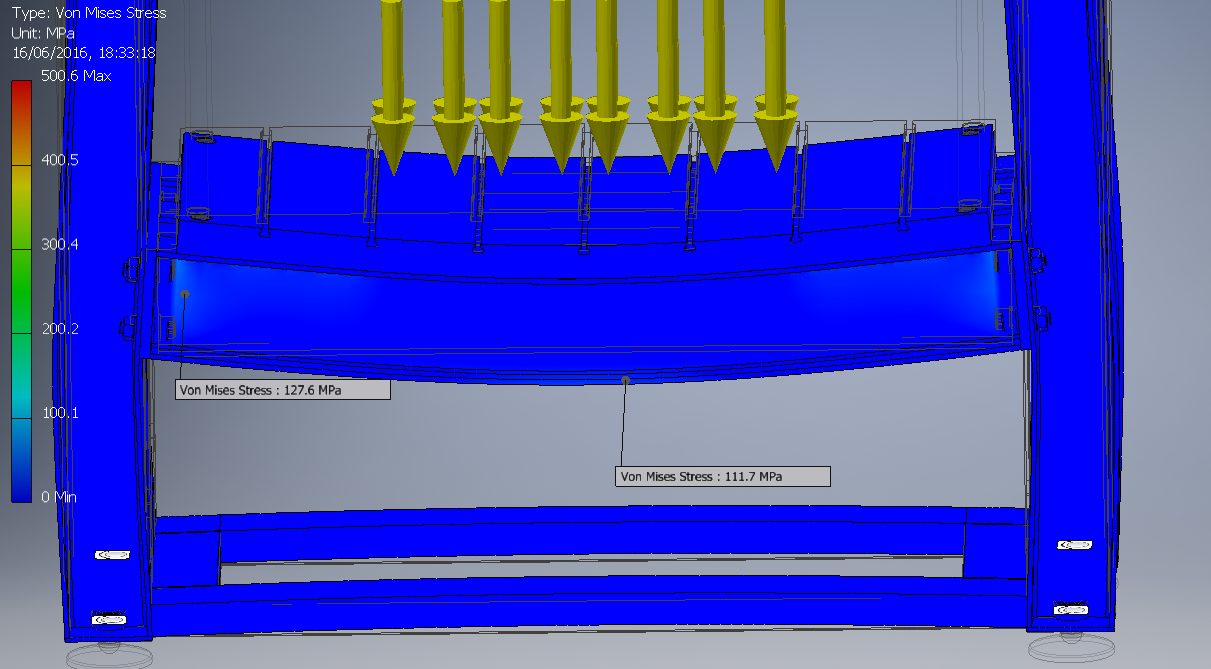

Design

Design

Press units are based on proven principles and can be tailored to the client’s requirements. All press units are designed with an infinite fatigue life on all fixed components. The major components can withstand more than 1×106 cycles without failure and are provided with preventative maintenance schedules to provide years of problem free operation.

All press units incorporate tried and tested modular servo/screw units which can be incorporated into any machine layout as desired.

FAQ’s

What are Ball Screw Presses?

Ball screw presses are a type of machine that uses a ball screw to operate it. They’re used to manipulate metal in a range of ways and here at Cambridge dynamics, we use them to produce precise and quality materials for everything from car parts to household electricals.

There are a few different types of ball screw presses that all have different outcomes. Here’s a few of the screw ball presses we have available:

· There’s the assembly press which is one of the easiest ways to permanently and securely connect compounds or parts, or form elements of a machine or device using a specific level of pressure.

· A punch and stamp press is a type of ball screw press that means you can stamp or press a large volume of components quickly and easily. These are the perfect option if you want precision, even for the most complex of components.

· Another type of ball screw press is the forming press. This involves shaping a piece of metal and stamping it between ‘dies’ through the application of pressure. This type of press can also roll, turn, blank and emboss metal.

With our years of experience, we at Cambridge Dynamics pride ourselves on the knowledge we’ve built up. To find out more about the type of ball screw presses and the services we offer, get in touch now by calling 01480 459555 or email us at enquiries@cambridgedynamics.co.uk and one of our team will get back to you as quickly as possible.

What are Ball Screw Presses used for?

With so many types of ball screw presses, the results are very different, meaning they can be used in a wide variety of industries. They’re much quicker than traditional forms of machinery, and can produce precise and intricate shapes in high quantities.

A ball screw press is often used to cut, shape and manipulate metal, including punching holes in sheets of metal. This is a much quicker and more effective way compared to drilling or cutting, as it’s less likely to tear or damage the rest of the metal. Any type of industry expects precision in their materials, and ball screw presses are the perfect way to achieve this.

When composite metals are produced using a ball screw press, they can be used for materials in aerospace and automotive industries, due to their strength and durability. The main benefit of composite metals is their ability to conduct electricity, making them perfect for electric cables and computer chips.

Without realising, many of our day-to-day products and appliances are made using ball screw press units, like cutlery and car parts. A forming press creates precise shapes across large amounts of materials in a short amount of time.

Ball screw presses are used to produce a wide range of products out of various materials,efficiently and in a much smarter way than other machines. Their popularity in industry is down to the volume they can produce at one time, meaning they’re invaluable in the modern day.

How does a Ball Screw Press work?

Although there are different types of ball screw presses, they all work by using varying levels of pressure to bend and shape materials into a wide range of products.

The ram is driven up and down by a ball screw (hence the name) to manipulate material into the desired shape. Each type of press has a slightly different process, creating different finishes and strengths for multiple types of products.

Stamping presses, for example, use dies to create the shape, whereas a punch press cuts the shape out of a large piece of metal. When you’re looking into ball screw presses, it’s important you provide the company (like us at Cambridge Dynamics) with as much detail as possible, so you can get as precise an outcome as possible.

A composite press on the other hand is a lot more complex, due to the precision that is expected from what they produce. A composite mold is placed into the press and heated up. When the chosen composite materials are put in, the composite press is activated using high pressure to force the material into a specific shape.

Overall, the main and most important part of the ball screw press is the pressure level and temperature. Getting these right is vital in the material manipulation process. If not done correctly, it can ruin the whole batch.

Need more information about ball screw presses? Get in touch today and one of our experts will be in touch to answer any of your questions.