Here at Cambridge Dynamics, we put punch and stamp presses in the same category, due to using the same machine for both.

However, the way they work is slightly different, producing outcomes specific to the customer’s project needs.

So, what are the key differences between these tools?

Today, we’ll explain what punch and press stamps are, and which one you’ll need for your project.

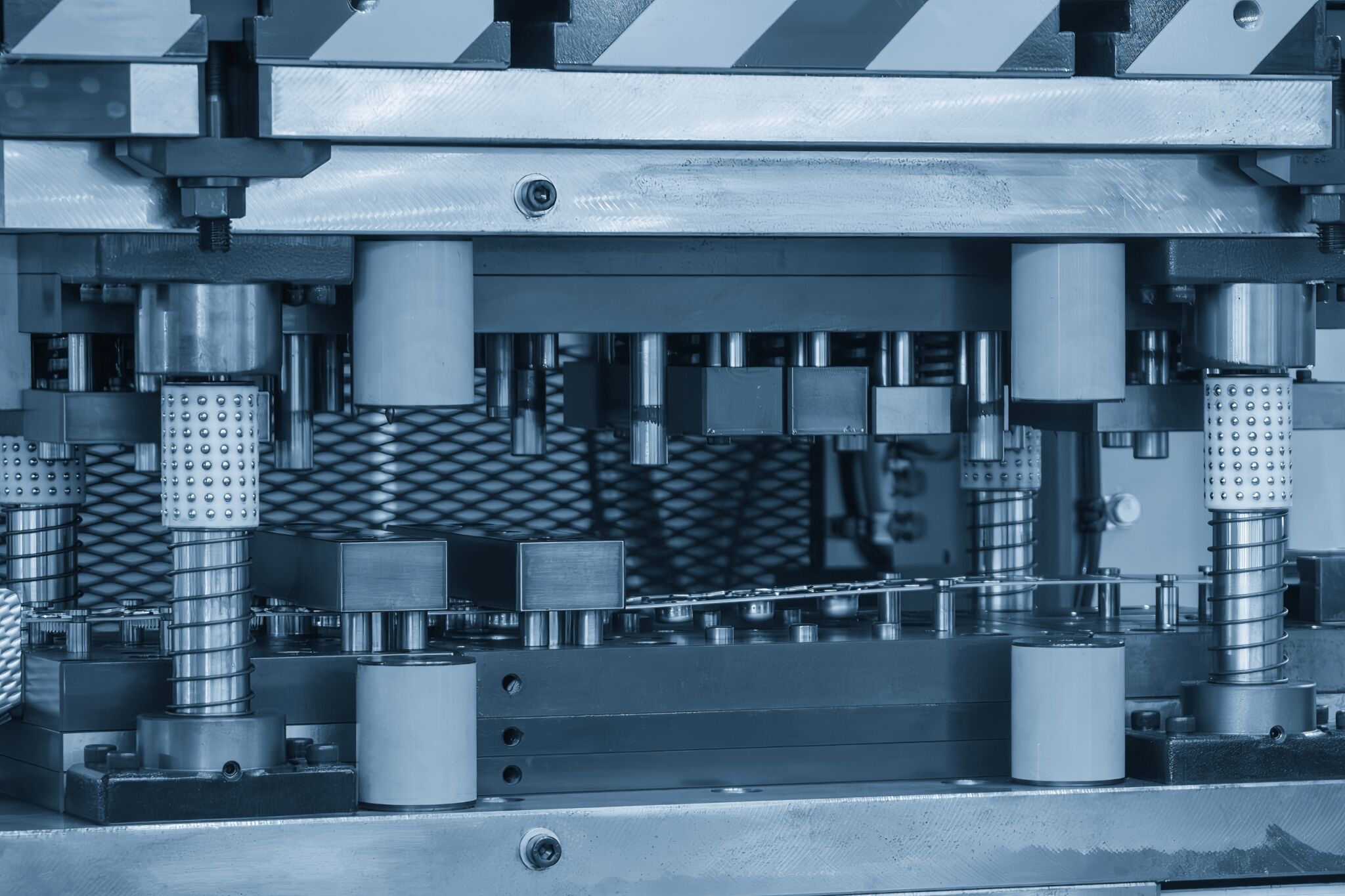

Punch press machine

A punch press machine changes the size and shape of a piece of material. The ‘punch’ element refers to cutting out a specific shape.

Stamp press machine

Stamp press machines also manipulate the shape of a piece of metal, but no shapes are punched out.

It is common for stamping and punching to be used in conjunction with one another – stamping tends to be done first, followed by the desired shape being punched out by a punch press machine.

How do they work?

A sheet of metal is placed between dies, and pressure is applied to create a certain shape. Within the machine, there is a punch or ram which pushes down on the material and shapes it around a die, secured by a thick plate (also known as a bolster plate) attached to the bed below.

There are numerous methods of control for these automation processes. Most machines use one of the following:

- Hydraulically Powered Drive: Hydraulic cylinders as an energy method promise an adjustable, smooth, and consistent stroke. This tool is also renowned for safety.

- A Clutch or Braking System: Guarantees optimal control, even with large machines. A clutch engages the flywheel, and the ram moves in turn. The brake can then intervene for ultimate precision.

- CNC (Computer Numerical Control) Technology: Used to control the punch press machine, offering a speedy service with flexibility, efficiency, and a high-quality result every time.

What are they used for?

Punch and stamp presses are used for a variety of projects in a range of different industries. Common pieces created by this type of press include nuts and bolts and electric terminals for home appliances.

To customise each piece, you can use these techniques to form a bespoke item:

- Hemming

- Riveting

- Centre-punching

- Countersinking

- Contouring

- Trimming

- Drawing

- Embossing

- Flanging

- Coining

- Bending

- Blanking

The option you choose depends on your design preference and project needs – all are available right here at Cambridge Dynamics.

What are the benefits of punch presses and stamp presses?

Many industries rely on stamp and punch presses due to how customisable they are.

Custom die sets can be made to create highly specific shapes, designs, and finishes, depending on your preferences and project needs.

By using computer-controlled machines, punch presses and stamp presses are highly reliable, as the same result is guaranteed every time and can be replicated as and when you need it.

It’s also a highly cost-effective way of manipulating metal without compromising accuracy – with the ability to operate at high speed, produce less waste, and make fewer mistakes, you can relax knowing the process won’t blow your budget.

There is less labour involved than if someone were to stamp and press materials manually, keeping costs as low as possible.

Do I need a stamp press or a punch press for my project?

Not every project requires a punch press or stamp press, but they do come in handy.

If you want to enhance productivity but don’t have time to test out different machines and don’t have the budget for wasted materials or mistakes during a press run, then it’s worth looking into.

One of the best things about using a stamp or punch press with CNC technology is that you can save the design to use again whenever you next need it. This also saves time and money, making the process an affordable one.

Get in touch to find out more

If you think you’d benefit from a stamp press or punch press, you’re in the right place.

Cambridge Dynamics is made up of an expert team who are on hand to offer professional services and assistance to all of our customers.

If you have any questions, you can call us on 01480 459 555 to chat with us directly, or send them to enquiries@cambridgedynamics.co.uk and we’ll get back to you as soon as we can.